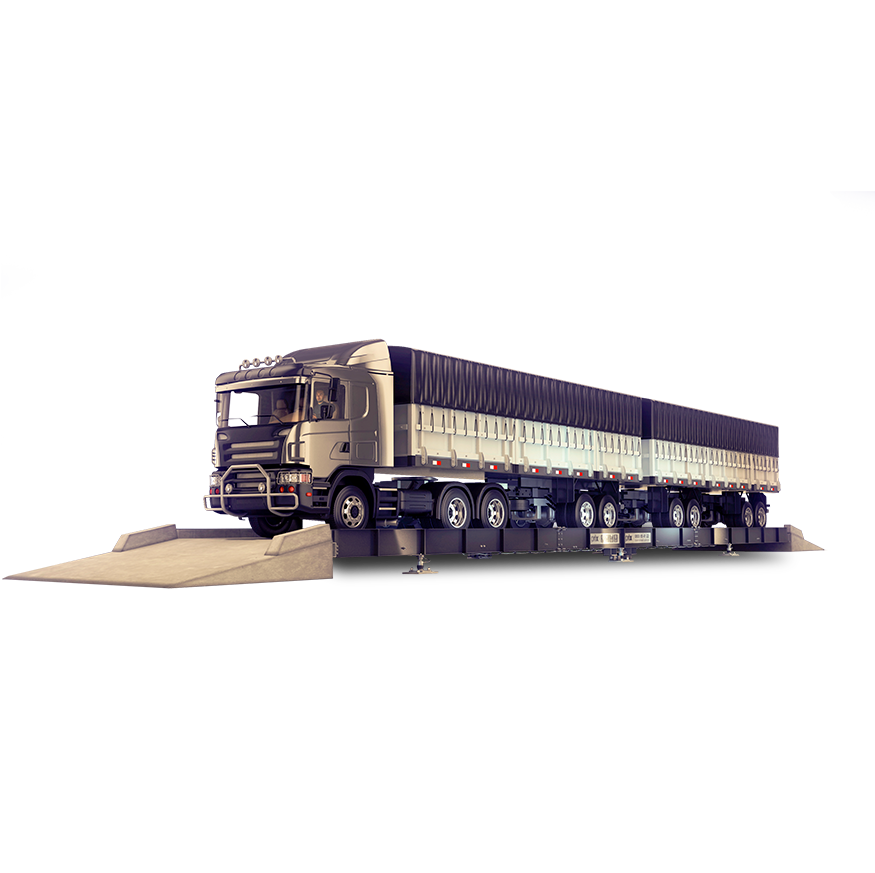

Construção e Montagem das Balanças Rodoviárias Prix: Eficiência, Inovação e Precisão.

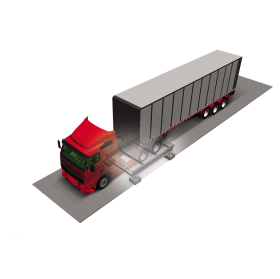

A construção de uma balança rodoviária exige etapas detalhadas e precisão em cada processo. Na Toledo do Brasil, trabalhamos com uma metodologia para garantir que cada projeto seja executado com qualidade, segurança e eficiência. Confira as etapas principais dessa jornada:

Especificações técnicas

Células de Carga

Células de carga digitais e inteligentes nos modelos PRIX e PDXTerminais

• TI420; • TC420; • IND570; • IND780Modelos

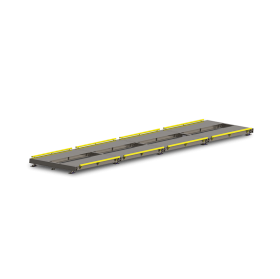

Modelos São dois modelos: 950i e 900i. Ambos possuem versão sobre o piso, semiembutida e embutida ao chãoCabos

Os cabos de interligação são blindados, resistindo a ambientes agressivos e à ação de roedoresFale com a gente!

Compare com

produtos semelhantes:

Você também

pode precisar:

Sugestões de produtos de outras categorias e itens acessórios