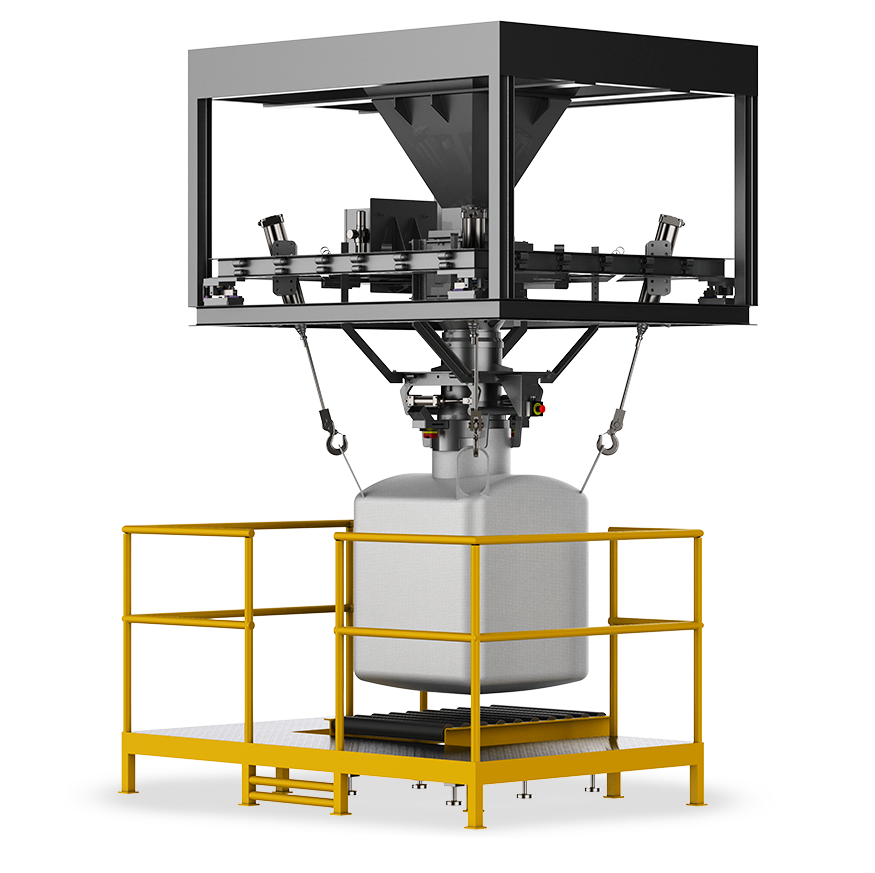

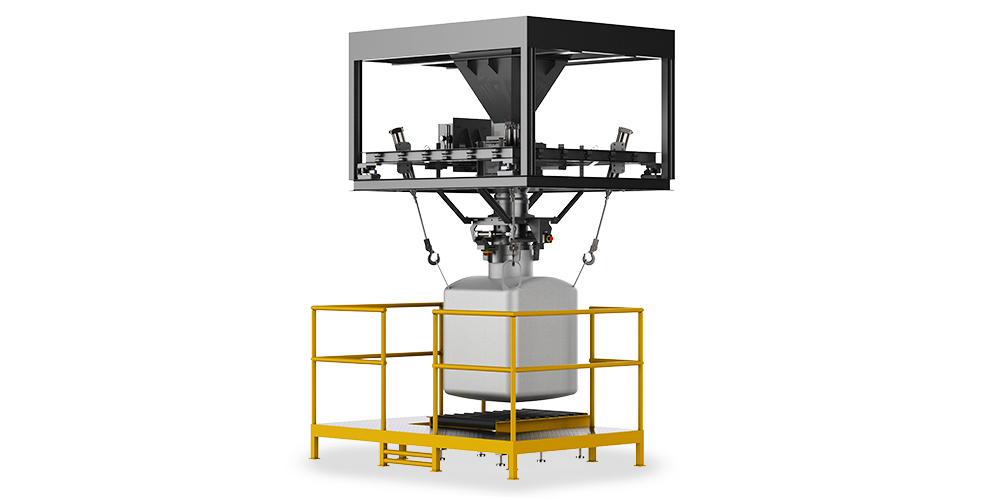

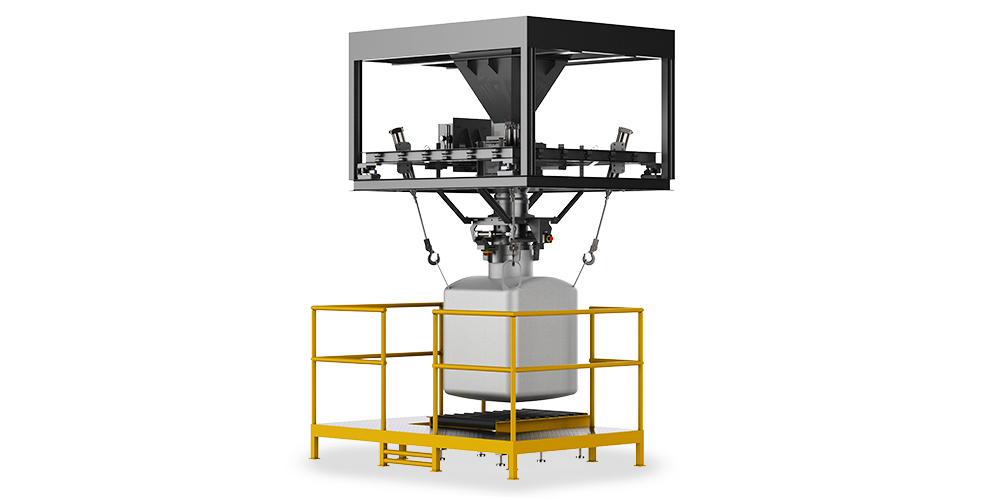

Especificações técnicas

Capacidade de pesagem

Até 40 big bag/hora com enchimento de 1200 kg por bag.Comunicação

Protocolos Fieldbus (Modbus TCP, Profibus, Profinet e Ethernet IP), RS-232 (para microcomputador e impressor) e Ethernet TCP/IP.Operação

Indústria alimentícia, mineração, construção, sementeiras, etc.Rastreabilidade

Impressão de etiquetas e envio de dados para banco SQL.Fale com a gente!

Compare com

produtos semelhantes:

Você também

pode precisar:

Sugestões de produtos de outras categorias e itens acessórios